Conformal Coatings: Safeguarding Electronic Components

- VAJRA

- Aug 4, 2023

- 2 min read

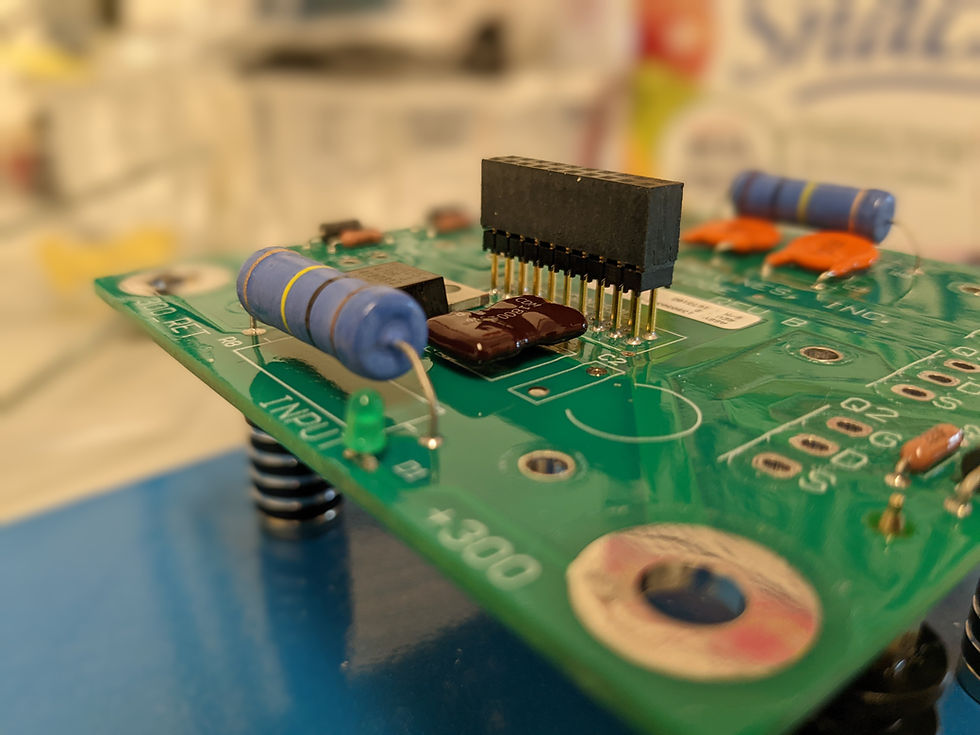

Conformal coatings are thin, protective films that are applied to electronic components and assemblies to shield them from a variety of environmental hazards. By creating a barrier between the components and the environment, conformal coatings prevent moisture, chemicals, vibration, and shock from compromising the integrity and performance of sensitive electronic parts.

Different types of conformal coatings exist, each with its own set of advantages and limitations. The most commonly used ones include:

Acrylic coatings: Ideal for general-purpose protection due to their transparency, hardness, and ease of application. However, they are not as resistant to chemicals as some other types of conformal coatings.

Silicone coatings: Flexible and resistant to chemicals, making them a great choice for components exposed to vibration or shock. They also maintain good dielectric properties without interfering with electrical performance. However, they can be more expensive than other types of conformal coatings.

Urethane coatings: Known for their toughness and chemical resistance, they suit components operating in high-temperature or harsh environments. Urethane coatings also offer excellent electrical properties. However, they can be more difficult to apply than other types of conformal coatings.

Parylene coatings: Extremely thin and conformal, making them perfect for space-limited applications. They excel in protecting components against moisture and chemicals. However, they can be more expensive than other types of conformal coatings.

The choice of the most suitable conformal coating hinges on the specific application, considering factors such as the operating environment, component type, and desired level of protection. For instance, components exposed to harsh conditions may benefit from a tough and chemical-resistant urethane coating, while those facing vibration or shock may require a flexible and chemical-resistant silicone coating.

Conformal coatings offer numerous benefits, including:

Moisture protection: Preventing corrosion and other issues caused by moisture exposure.

Chemical protection: Shielding components from chemicals that could damage or impair functionality.

Vibration and shock protection: Safeguarding components from damage due to vibration or shock.

Improved electrical performance: Mitigating electromagnetic interference (EMI) and enhancing electrical performance.

Extended lifespan: Prolonging the life of electronic components by shielding them from the environment.

Advancements in conformal coating technology encompass:

New materials: The latest trends in conformal coating include the development of new materials and techniques. For example, new silicone coatings are being developed that are more resistant to chemicals and moisture. New urethane coatings are being developed that are more resistant to high temperatures. And new parylene coatings are being developed that are thinner and more conformal.

New application techniques: Researchers are devising novel techniques for applying conformal coatings, streamlining the process and achieving more consistent coating thickness. For example, researchers have developed new methods for applying conformal coatings using robotic arms.

Conformal coatings play a crucial role in electronic design and manufacturing. By shielding components from environmental hazards, they promote reliability, extend lifespan, and ensure optimal performance. As trends in conformal coating technology continue to evolve, these coatings will become even more potent in safeguarding electronic components.

Email us today at info@vajramicro.com to discuss your conformal coating needs.

Bình luận